Productos

Zirconia-Ce Ball Mill CS-62. product name: ceria-stabilized zirconia beads. product category:. ceramic grinding media. product details:. cs-62 series zirconia-ce ceramic 3. Horizontal and vertical sand mills Zirconia beads are widely used in high-efficiency grinding equipment in industries such as coatings and paints, magnetic coatings, cosmetics raw It is recommended to use 2.0-3.0mm zirconia beads. 5. Rod pin horizontal sand mill: It is one of the revisions of the traditional horizontal sand mill, which changes the dispersion plate into rod They’ve come up with a high-tech grinding process that makes this milling media solid, from surface to center. This technique, results in a stronger With Zirconia Silicate beads, some of the machines that are compatible with them include: Horizontal sand mills these are ideal for dispersion applications such as inks, paints, and coatings. These are a preferred option since loading Mar 04, 2022SZS Zirconium Silicate Beads are manufactured from world-class premium zircon (ZrSiO4) mineral in a special high temperature sintering process. Because of its outstanding breakage resistance and the Nov 02, 2021After grinding, the high-speed rotating hard tungsten steel separation gap is output to the outside of the grinding cylinder. This is a cycle grinding operation, and the continuous Dec 29, 2021According to its performance, it can be roughly divided into horizontal sand mills, basket sand mills, and vertical sand mills. It is mainly composed of a machine body, a NETZSCH- Beads® Take Advantage of the Benefits Grinding beads ideally adapted to NETZSCH agitator bead mills All important qualities are available in the requested sizes 3. Horizontal and vertical sand mills Zirconia beads are widely used in high-efficiency grinding equipment in industries such as coatings and paints, magnetic coatings, cosmetics raw materials, electrostatic copying powder for photographic copying, filling materials for stone making and , such as vertical and horizontal sand mills. Pesticides Dispersion Horizontal Sand Mill Grinding Media Sintering Zirconium silicate Zirconium Silicate beads is of high-tech grinding process by sintering and phasing method that makes this milling media solid from surface to center. This media can be used in both horizontal mills well as the vertical mill. It consists of 65 percent of zirconia and the rest is Silicon Dioxide (SiO2) and Aluminum Oxide (Al2O3). Inovatec offers the following milling machines for Zircosil beads, are of upper medium density (4.4 g/cm 3) tough and sapphire hard (9 Moh’s scale), ideally suited for speedy dispersion / milling of hard and soft substances in high-low speed, horizontal and vertical type bead mills, sand mills, attritor, turbo and pearl mills. It is recommended to use 2.0-3.0mm zirconia beads. 5. Rod pin horizontal sand mill: It is one of the revisions of the traditional horizontal sand mill, which changes the dispersion plate into rod pin. Zirconia beads with a particle size of 0.6-2.0mm are usually used as the grinding medium. 6.Turbine horizontal sand mill: They’ve come up with a high-tech grinding process that makes this milling media solid, from surface to center. This technique, results in a stronger molecular structure, which increases density and wear resistance. Itss the reason no Tissue grinding CKMix50, 15mL Mix of 2.8.. and 5.0mm Zirconium oxide beads 15mL pre filled tubes ; Lysing kit for Precellys CKMix50 Tissue kit 15mL tubes 25 prep. The CKMix50 matrix is composed of a dual ceramic (zirconium oxide) bead type of 2.8mm and 5.0mm and is recommended for hard. Compare this item. This lab mill is an ideal size for testing small amounts of material. Results from the DMQX® Bead Mill may be scaled up to production size models. Features/Benefits Operates in either circulation or continuous mode SZS Zirconium Silicate beads are manufactured from world-class premium zircon (ZrSiO4) mineral in a special high temperature sintering process. Because of its outstanding breakage resistance and the advantageous price, this medium density bead is particularly suitable for use in large-volume agitated bead mills. Bead Mill is a revolution of horizontal mills and was developed in 2008 as high energy and high flow recirculation type mill. This mill uses high energy milling discs for maximum dispersion and grinding efficiency in smallest possible chamber. Best Quality Zirconia Beads for Milling and Grinding Supports ultrafine polishing and milling Can be used in vibratory mills, stirred mills, horizontal mills High-quality zirconia beads that are resistant to wear and tear Beads available in sizes from 0.3mm to Mar 04, 2022SZS Zirconium Silicate Beads are manufactured from world-class premium zircon (ZrSiO4) mineral in a special high temperature sintering process. Because of its outstanding breakage resistance and the advantageous price, this medium density bead is particularly suitable for use in large-volume agitated bead mills. Bead Mills The high energy media mill can impart more energy to milling media for dispersion than other conventional mills. The geometry of the energizer dispersion tool fluidizes the milling media in toroidal flow pattern to form high energy concentration zones through out the milling chamber. Horizontal Bead Mill REQUEST CALLBACK Get Best Quote SeFluid's bead mill for super fine milling; ceramic hard wetted parts; ideal for paint, ink, pesticide, rubber and various industrial purpose production. Skip to content Call Us: +86 156 6910 1862 sales@sefluid Zircosil beads, are of upper medium density (4.4 g/cm 3) tough and sapphire hard (9 Moh’s scale), ideally suited for speedy dispersion / milling of hard and soft substances in high-low speed, horizontal and vertical type bead mills, sand mills, attritor, turbo and pearl mills. They’ve come up with a high-tech grinding process that makes this milling media solid, from surface to center. This technique, results in a stronger molecular structure, which increases density and wear resistance. Itss the reason no While glass (silica), zirconium and stainless steel beads are all effective at disrupting cells and tissues. The added density of zirconium and stainless steel beads helps to yield better homogenized samples. Related Products: Pre-filled Bead Tubes Compare this item Bulk Ceramic 0.1mm beads, 400g Bertin Corp With Zirconia Silicate beads, some of the machines that are compatible with them include: Horizontal sand mills these are ideal for dispersion applications such as inks, paints, and coatings. These are a preferred option since loading Zirconia Ceria stabilized beads offer the highest density, optimized wear resistance, and cost effectiveness as an efficient milling media. Horizontal Lab Bead Mill; Model: LME 1: Mill Capacity: 0.61 Ltr: Ceramic Media (Qty.) 2.35 kgs. Make NETZSCH, Germany; Mill Container: Polyurethane: Mill Agitator Speed: 3000 RPM: All-round Horizontal Beads Mill (60-200L) All-round Horizontal Beads Mill is a Nano Grade liquid grinding machine for closed continuous production. Comparing with traditional grinding equipment, it uses Yttrium stabilized zirconium beads with higher specific gravity and higher hardness as grinding medium. This lab mill is an ideal size for testing small amounts of material. Results from the DMQX® Bead Mill may be scaled up to production size models. Features/Benefits Operates in either circulation or continuous mode The utility model discloses a horizontal zirconium bead grinder. The horizontal zirconium bead grinder provided by the utility model can grind high-viscosity mill base and has high grinding efficiency. The horizontal zirconium bead grinder comprises a power device, a stirring shaft, stirring vanes, a horizontally arranged grinding bucket and a delivery pump, wherein the power Jan 11, 2021The common is zirconium silicate beads and pure zirconia beads. ELE bead mill not allowed to add zirconium silicate beads to mill. We recommended to add pure zirconia beads with a zirconium content of more than 95%, with a bulk density of 3.65 -About 3.7g/cm3. Jan 11, 2021 ELE bead mill not allowed to add zirconium silicate beads to mill. We recommended to add pure zirconia beads with a zirconium content of more than 95%, with a bulk density of 3.65 -About 3.7g/cm3. How to measure whether the zirconium beads you choose are pure zirconium oxide beads, Here is a simple test method. The maxi line of self-contained horizontal bead mills for laboratory applications consists of 0.5, 1, and 2-liter models.the mills are suitable for use with steel, glass, alumina, or zirconium beads from 0.5 to 3mm.they accept laboratory samples from 500 mls to 5 liters or small scale batches from 5 to 50 liters. Bead Mills The high energy media mill can impart more energy to milling media for dispersion than other conventional mills. The geometry of the energizer dispersion tool fluidizes the milling media in toroidal flow pattern to form high energy concentration zones through out the milling chamber. Horizontal Bead Mill REQUEST CALLBACK Get Best Quote Nov 07, 20214.Zirconia beads backlog: if zirconia beads are stacked at the bottom of the sand mill or the speed of the working pump is too fast to lead to zirconia beads are concentrated in the exit of the horizontal sand mill, it will lead to this situation.The solution is to start the sand mill by “on off on off” point to loosen the backlo... Lab Horizontal Beads Mill-C is a Nano Grade liquid grinding machine with high performance for labs of collages, research institutes and factories. It is application for liquid materials with low and mid viscosity. The machine is equipped with a dosing pump with adjustable flowrate based on different materials to obtain the optimized result.

Zirconium Beads Horizontal Mills

Zirconia Beads are used in the mill

How to match different zirconium beads to the grinder

Zirconium Bead ACECHEM RESOURCES

Zirconia Silicate Beads, Milling, Dispersion, Grinding

CHEMCO's World Class Sintered Zirconium Silicate Beads

How Many Types of Bead Mills Do You Know? Allwin

The Advantages of Horizontal Bead Mills in the Dye Industry

NETZSCH-Beads ProductsSolutions GrindingDispersing

Zirconia Beads are used in the mill

Pesticides Dispersion Horizontal Sand Mill Grinding

Zirconium Silicate Beads, Milling, Dispersion,

Zirconium Silicate Milling Beads Zircosil Jyoti Ceramic

How to match different zirconium beads to the grinder

Zirconium Bead ACECHEM RESOURCES

Zirconium Bead at Thomas Scientific

DMQX-Series Union Process

Zirconia Beads, Partially Stabilized with Yttria CHEMCO Ceramic Beads

Bead mill, sand mill, Perl mill, dyno mill, small media mill

China Top Zirconia Beads Manufacturer and Supplier Inovatec

CHEMCO's World Class Sintered Zirconium Silicate Beads

Bead Mills Horizontal Bead Mill Manufacturer from Coimbatore

Bead Mill Sand SESM40 Pearl Mill super fine SeFluid

Zirconium Silicate Milling Beads Zircosil Jyoti Ceramic

Zirconium Bead ACECHEM RESOURCES

Zirconium Bead at Thomas Scientific

Zirconia Silicate Beads, Milling, Dispersion, Grinding

Zirconox Zirconia ceria stabilized beads Zirconox Micro Milling Beads

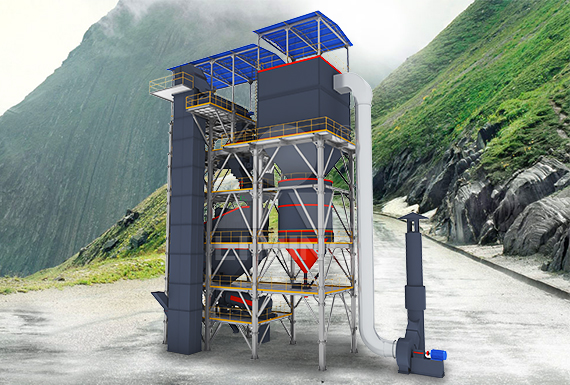

Horizontal Beads Mills m.sieheindustry

DMQX-Series Union Process

CN202860636U Horizontal zirconium bead grinder Google

What Is The Amount Of Zirconium Beads Added To The Bead Mill

zirconium beads horizontal mill

Zirconium Beads Horizontal Mills

Bead Mills Horizontal Bead Mill Manufacturer from Coimbatore

Normal loss of zirconium beads and abnormal bead breakage

Lab horizontal beads mill C working principle Siehe Industry